ID grinding, OD grinding, and ID honing are all precision machining processes used to achieve tight tolerances and high surface finish on cylindrical parts:

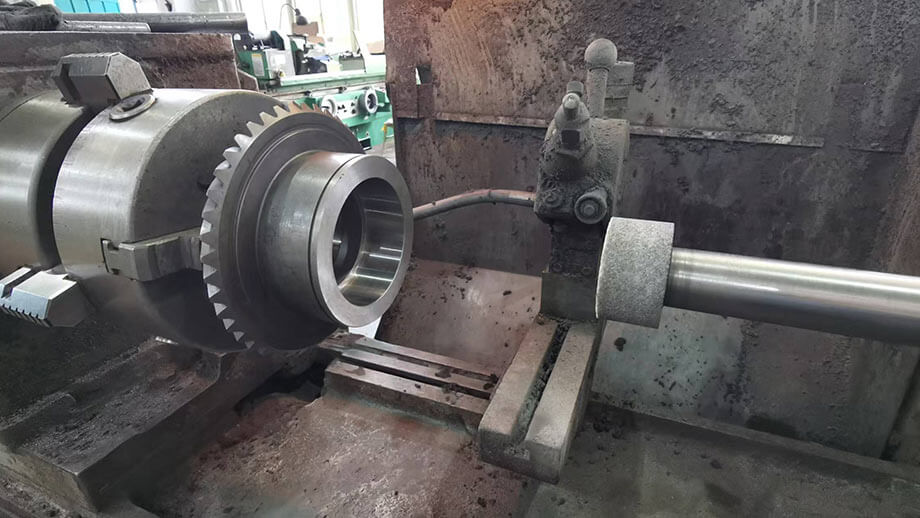

ID Grinding: This process involves grinding the inner diameter (ID) of a cylindrical part. It is commonly used to produce precise bores and holes in a variety of materials, including metals, ceramics, and plastics.

OD Grinding: OD grinding or external diameter grinding, is the process of grinding the outer surface of a cylindrical part. It is used to achieve precise dimensions and a smooth finish on the outside of the part.

ID Honing: Honing is a machining process that uses an abrasive stone or tool to remove small amounts of material from the inner diameter of a part. It is typically used to improve the surface finish and dimensional accuracy of a bore or hole.

We offer competitive pricing on gear manufacturing services, whether you need complete gear manufacturing or a single service, and our quality can’t be beat. Contact us for a quote today.